9/11 Museum

February 11, 2015New York, NY

Maintaining a National Treasure

Modern facility architecture often involves grand elements that add to the customer experience high ceilings, unusually shaped facades, glass atriums and plenty of open space. As aesthetically pleasing as these elements may be, they present a big challenge for those responsible for day-to-day maintenance and upkeep.

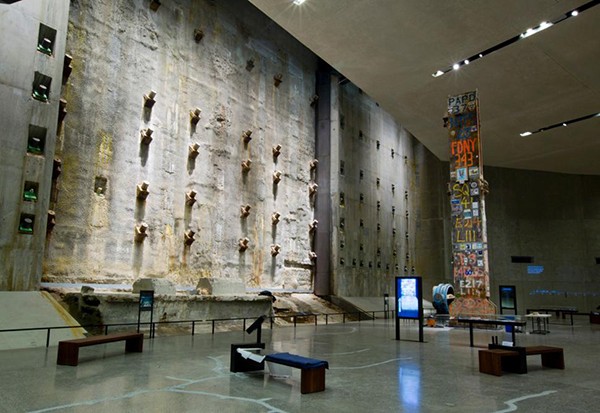

The National September 11 Memorial Museum in New York is no exception. This facility, the memorial built to honor the victims of the 9/11 terrorist attack, is located underground in the foundations of the two original World Trade Center towers. Among the emotionally powerful architectural features is Foundation Hall. The room contains the surviving retaining wall (called a "slurry wall") of the World Trade Center and has a ceiling nearly 80 feet high.

Clearly changing a light bulb or accessing sprinklers or ceiling ventilation is an issue here, as it is for anyone maintaining a modern museum, university building, healthcare facility, shopping mall or corporate center.

For Dreu Beers, Director of Engineering at the 9/11 Memorial, a traditional maintenance solution wouldn't do. Therefore, he chose a LEO Series compact track lift from Teupen USA for a variety of reasons specific to the museum world.

"It's not just a matter of the high ceiling, because otherwise a scissor lift could do the job," says Beers. "In Foundation Hall, we have exhibition pieces such as the Last Column, the column that symbolizes the close of the recovery effort at Ground Zero. Obviously, it's a one-of-a-kind, very special piece. When we're doing maintenance, we need to work around the Column and other items in the exhibition, so we need precision and flexibility of movement in our lift equipment. We need to not only move up, but up, over and across."

Beers says he has the option of using scaffolding, but that system is particularly problematic for maintaining normal museum operations, especially at a museum with such a high volume of visitors. "Scaffolding takes a long time to set up, usually a day," he explains. "Then work happens the next day, and you have to close or section off that area in the meantime. This affects our revenues and attendance. And anyone can tell you, there's nothing pretty about scaffolding."

With Teupen's LEO machine, Beers says he can move the equipment in and out quickly; and if work needs to continue the next day, the lift is easily stored out of the way. The compact design of the machine allows it to move easily through double doors or any tight spaces where other lifts can't travel.

Beers adds that the low floor load rating is another plus. "We don't want heavy lifts moving over our floors," he says. "This unit is under 7,000 pounds, and a normal lift can be more than 30,000 pounds. That's a lot of pressure on a floor, and it's unnecessary when you have the option of using the LEO."

In addition to the 9/11 Museum, Teupen USA provided equipment for other buildings in the new World Trade Center complex as well. Our lifts were used in the construction process for seven new buildings throughout this city block in lower Manhattan.

The most pressing need for our equipment was on the exterior of one of the buildings. A conventional boom lift was simply too heavy for transport in an exterior elevator. But with the lighter weight of a Teupen lift, contractors were able to bring the machine all the way to the 80th floor to handle the necessary construction elements. Our equipment allowed for the access and precise control that a scissor lift couldn't provide.

At Teupen USA, we value all our clients; but our connection to The National September 11 Memorial Museum is especially rewarding. We are very proud and honored that our equipment is considered critical to operations at a museum that means so much to our nation and stands as a symbol of hope and freedom to people around the world.